WHETSTONES

Our Whetstones – for sharpening at the highest level. Perfect for beginners and professionals alike.

Our whetstones in detail

Professional sharpening with our whetstones

Sharp blades don’t just make cutting a pleasure — they also enhance safety. But even the finest edges eventually become dull. With our ULTIMATE Whetstones and the PRO Sharpening Stone Set, dull blades are a thing of the past.

These sets bring your knives to a level of sharpness that can split hairs — and help maintain that edge over time.

Thanks to their superior sharpening performance, Culilux whetstones aren’t just trusted by professionals – they also make it easy for beginners to achieve excellent results quickly.

ULTIMATE Whetstones

The ULTIMATE series stands for uncompromising top quality. Made from high-quality aluminum oxide with a magnesia binder, these stones deliver outstanding sharpening performance with minimal wear and an exceptionally smooth sharpening feel.

Recommended for users who appreciate the quality of Japanese high-end whetstones, as well as for ambitious beginners who want to invest in top-tier quality from the very start.

Components of the bundle

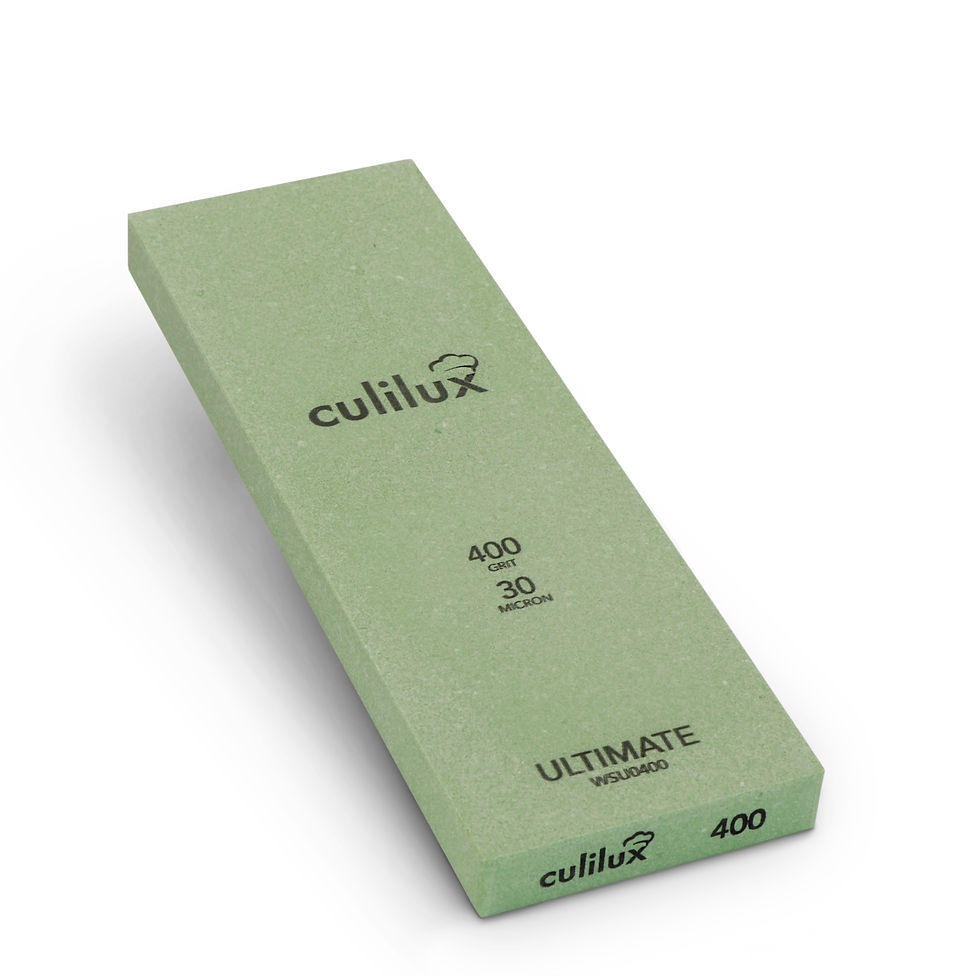

WHETSTONE 400 GRIT

The 400 grit has the fastest speed of abrasion and is used to grind the cutting edge into the desired shape and angle. It's also used to repair a chipped cutting edge.

WHETSTONE 1000 GRIT

The 1000 grit is used to refine the surface of the cutting edge after sharpening on the 400 grit. When the edge is only worn slightly, sharpening can also be started on this grit.

WHETSTONE 3000 GRIT

The 3000 grit is used to further refine and pre-polish the cutting edge. It can also be used to restore the sharpness when a leather strop can't bring the edge back any more.

LEATHER STROP

The cutting edge receives its final refinement and polish on the stropping block.

A polished cutting edge glides through food with little resistance and not only increases the perceived sharpness, but also the measured one.

SHARPENING BASE

The sharpening base made of durable plastic with non-slip rubber feet ensures a secure hold during sharpening and prevents the stones from slipping.

It’s also perfect for storing the ULTIMATE whetstones – neat, stable, and practical at the same time.

CLEANING STONE

Over time, the pores of the whetstone become clogged, which reduces the cutting performance. The diamond cleaning/ dressing stone cleans quickly and effectively, restoring the stone’s original sharpening efficiency.

PRO Whetstone Set

The PRO series corresponds to high-quality Japanese whetstones of the grade just below the ULTIMATE series. It offers an outstanding price-performance ratio while still meeting professional standards. Ideal for sharpening and maintaining the sharpness of Culilux knives, the PRO Sharpening Stone Set is perfect for those looking to start their sharpening journey or achieve consistent results at an attractive price.

Set Components

WHETSTONE 400 GRIT

The 400 grit has the fastest speed of abrasion and is used to grind the cutting edge into the desired shape and angle. It's also used to repair a chipped cutting edge.

WHETSTONE 1000 GRIT

The 1000 grit is used to refine the surface of the cutting edge after sharpening on the 400 grit. When the edge is only worn slightly, sharpening can also be started on this grit.

WHETSTONE 6000 GRIT

The 6000 grit is used to further refine and pre-polish the cutting edge. It can also be used to restore the sharpness when a leather strop can't bring the edge back any more.

LEATHER STROP - FLESH SIDE

The cutting edge receives its final refinement and polish on the flesh side of the stropping block.

A polished cutting edge glides through food with little resistance and not only increases the perceived sharpness, but also the measured one.

LEATHER STROP - GRAIN SIDE

The last sharpening step is the final deburring on the smooth grain side of the leather. This will leave with with a perfectly clean, sharp and polished cutting edge.

In everyday use, blades should be stropped on the grain side whenever they start losing their sharpness.

CLEANING STONE

Over time, the pores of the whetstone become clogged, which reduces the cutting performance. The diamond cleaning/ dressing stone cleans quickly and effectively, restoring the stone’s original sharpening efficiency.

SHARPENING BASE WITH NON-SLIP FRAME

The practical sharpening base has rubber feet to prevent slipping and brings the stones to a comfortable sharpening height. Its inner space can collect the sharpening slurry and additionally be used to store the sharpening accessories.

The silicone non-slip frame holds the stones on the sharpening base. It can also be used as a non-slip base without the sharpening base, e.g. with the stropping block.

ANGLE GUIDE

The angle guide is placed on the back of the blade and helps to keep the angle steady during sharpening at about 15-20°. Holding a steady angle is essential for a good sharpening result.

Benefits of our whetstones

FASTER SHARPENING

PRO Whetstones: In the CST process (Cold Sintering Technology), the stones are sintered at low temperatures, which increases the density of abrasive particles.

This results in faster sharpening performance comparable to that of high-quality Japanese stones.

It also allows a pronounced burr to form more quickly, making sharpening significantly easier—especially for beginners.

READY TO USE INSTANTLY

The higher density also reduces the porosity of the material, meaning the stone absorbs less water and does not require long soaking like traditional stones.

For the PRO whetstones, a short soak or a few drops of water are sufficient, while the ULTIMATE stones are splash & go and only need to be sprinkled with water.

SAFE AND STABLE

Since whetstones are generally designed for use on both sides, hollow spots can form on each surface over time. This causes the stones to lose their flatness and wobble, making sharpening more difficult and reducing the quality of the results.

Our PRO stones are glass-backed, ensuring a perfectly stable surface that never wobbles. The ULTIMATE stones hardly dish due to their density. This allows safe sharpening with maximum pressure and speed at all times.

REDUCED WEAR

Since the higher density of both our ULTIMATE and PRO whetstones shortens the sharpening time, the wear on the stones is also reduced. This not only increases the service life, but also reduces dishing of the stones and thus makes sharpening easier.

The art of sharpening

SHARPENING

1. During sharpening, material is removed from both sides, in order to obtain a pointed cutting edge again.

2. The knife is held at an angle of approx. 10-15° to the stone.

3. The blade is moved back and forth at a 45° angle to the stone until a burr is created along the entire edge.

4. On the rear side only, the rear end of the cutting edge must be moved at a 90° angle.

REFINING THE EDGE

As soon as a burr is created on the coarsest grit, the cutting edge is refined by sharpening on the finer grit stones, which increases the sharpness.

As on the other stones, it is recommended to sharpen the blade in 3 sections, first the tip, then the middle, and finally the heel of the blade.

DEBURRING / STROPPING

After sharpening on the finest stone, the cutting edge must be completely deburred. This is done by stropping, with alternating strokes (front and back) first on the finest stone and then on the leather stropping block.

EDGE MAINTENANCE

To maintain the sharpness, the knife must be stropped on the stropping block as soon as paper or a tomato can no longer be cut cleanly.

If stropping is no longer sufficient to restore the sharpness, it must be sharpened again on a whetstone, using the 6000 or 1000 grit, depending on the condition of the cutting edge.